Introductory Mist-lining workshop

A two-day Mist-lining workshop in Antwerp by Marjan de Visser on April 7 and 8, 2025. This was organized by Restoration Studio Dewilde, Fine Art Restoration Mechelen, the non-profit organization De Kunstkliniek, and the Royal Academy of Fine Arts Antwerp (

DKO program in painting restoration/polychromy ). This hands-on workshop will include theoretical support.

Mist-lining in practice

This Mist-lining workshop focused on practical sessions, developing as much skill as possible in the technique, and sharing experiences. The 15 participants brought their own double-layered canvas on a frame and a test piece. The canvases varied from thin cotton, cotton-linen blend, unknown synthetic fabrics, pre-washed linen, unwashed linen, pre-prepared linen, and Trivera (synthetic). Some even used a Parafil RT 20 Polyester interlining (non-woven tissue).

Introduction to Mist-lining

This mist-lining technique is so unique because it’s low-budget, requiring no expensive equipment. It uses low pressure (a vacuum cleaner) and an extraction system consisting of perforated tubes. The bonding process is achieved through reactivation of the adhesive. Anyone can make the system themselves, and it’s suitable for all sizes of canvas paintings.

History Mist-lining

The technique was developed by Jos van Och (SRAL) in the 1990s. He is a student of Vishwa R. Mehra . Kate Seymore further developed the technique into the way it is taught today. She co-authored “De-Mystifying Mist-Lining” with Joanna Strombek.

Flakes glue layer

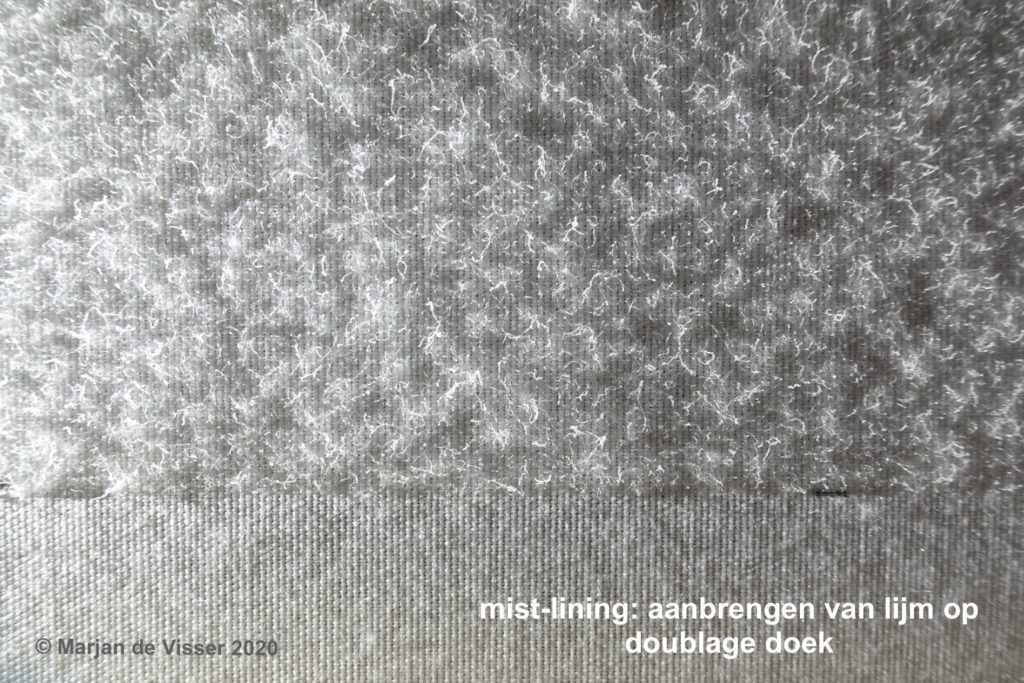

The principle is based on spraying the flaky adhesive layer onto the lining canvas. Applying low pressure ensures the painting receives the desired structural support with minimal intervention. Low-pressure mist-lining can be the best solution in several restorations. In the Restoration Workshop, mist-lining has been a solution for a number of paintings.

The mist-lining glue

During the Mist-lining workshop, six different adhesive mixtures were chosen in consultation: Dispersion K360 + Plextol D512 + Roagit© (thickener) in the ratios 70%-30% and 50%-50% with and without Roagit. The adhesive was sprayed straight from the front, but some sprayed at a 30-degree angle to the spray line to ensure better flocking. A 30 cm distance from the canvas was maintained at all times.

| Product | compsition | properties | pH |

Plextol D512 | Acryl polymeer dispersie | Min. film temp. 17 °C, Tg 26 °C. Solids content 50 %, pure acrylic. Flexible. | 8,0 |

| Dispersie K360 | pure acryl thermosplastic polymer dispersion, approximately 60% solids. | ||

| Rohagit © | Thickener, gel forming | Add drop by drop to the acrylic medium | 2,5 -4,0 |

| K360 70% | D512 30% | Roagit 2% |

| K360 70% | D512 30% | – |

| K360 50% | D512 50% | Roagit 2% |

| K360 50% | D512 50% |

Low Pressure Wagner paint sprayer

During the workshop, the adhesive layer was sprayed with the Wagner W450. This is especially useful if you don’t have a sprayer with a compressor.

The solvents

For the reactivation of the adhesive layer (day 2), two different solvents were tested. The activation time was 20 minutes and the vacuum time was 1.5 hours. The solvents were isopropanol and a mixture of isopropanol:MEK 50%:50%.

The cheesecloth for the reactivation of the solvent was chosen in two different thicknesses, this had an influence on the absorption of the solvent.

parameters

The various adhesive combinations and ratios, the diversity in double-layered textiles, and the angle of spraying provided much food for thought and opportunity for comparison of the adhesive layer and the adhesive strength.e lijmlaag en de kleefkracht.

Some conclusions

It makes no difference in flocking whether a 70-30 or 50-50 ratio was used. For one participant, 70-30 was better, while for another participant, the reverse was true. The Roagit didn’t really add anything. The textile backings, however, were decisive. Thin cotton and unknown synthetics yielded poorer adhesion than cotton-linen blends, linen, and Trivera. Pre-washed or unwashed made no difference. In some lining textiles, the adhesive penetrated the fibers to the back. Was the spray applied too closely? Was the fabric woven too openly? Sturdy linen roughens more easily and produces coarser flocking than synthetic Trivera. Overall, the results were good. One result remained, possibly because the adhesive layer was sprayed too thinly. A wrinkle in a washed linen double-layered fabric also shows up in the final result later, so iron it better!

Experiences

What matters most is the knowledge and experience gained. If something doesn’t yield the desired results, it’s a great opportunity to continue learning. The exchange, discussing results, and reviewing each other’s projects provides an additional opportunity to gain a lot of experience in a short time.

The equations of the glue and doublage textiles

The vacuum suction

The assessment of the results